3000L 5000L Glass Lined (enamel/GLR) and Stainless Steel (SS) High Speed & Pressure Mixing Reactor with Heating or Cooling Jacket/Condensor

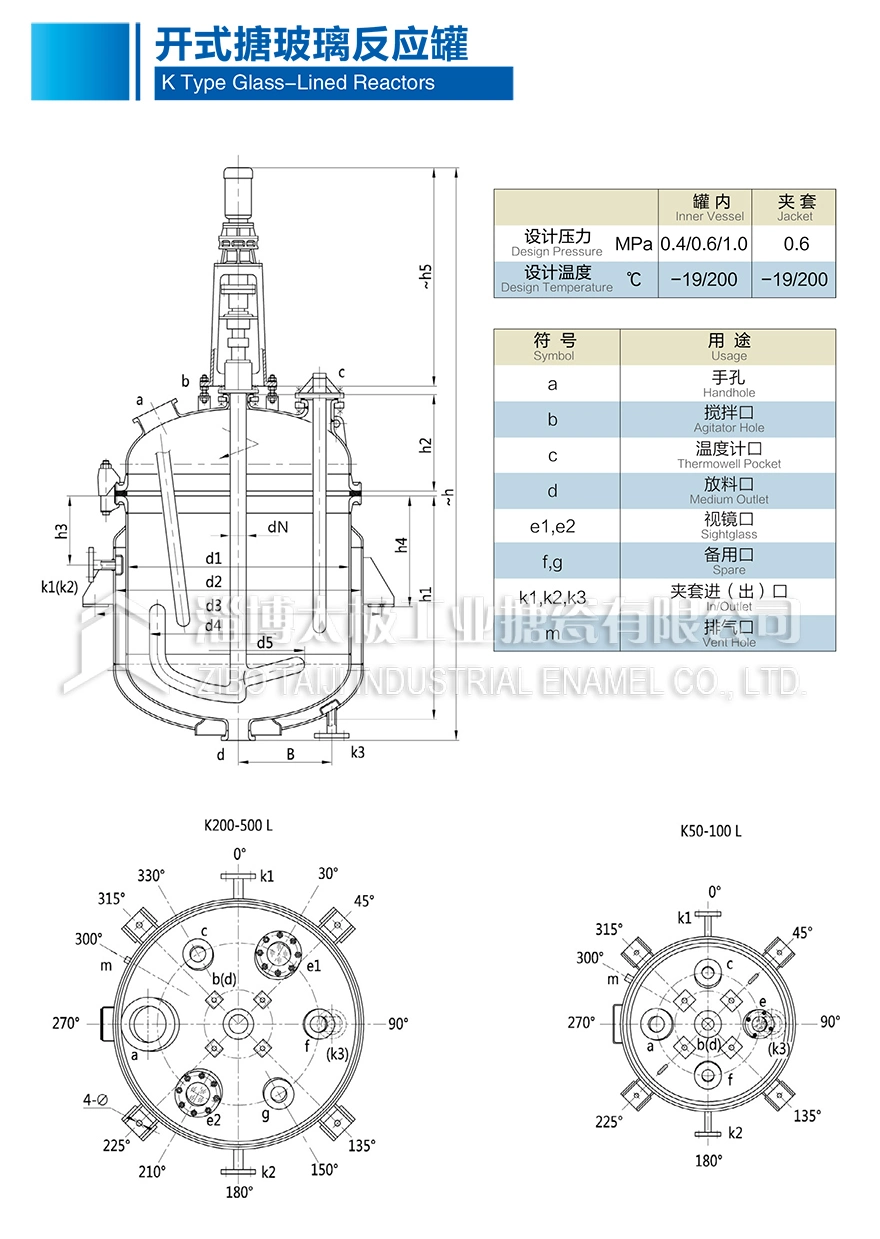

Product Name: K Type Glass Lined Reactors Another Name: Open Type Glass Lined Reactors Subordinate category: Glass Lined

Send your inquiryDESCRIPTION

Basic Info

| Model NO. | K type |

| Agitator Model | Turbine Agitator |

| Tower Reactor Type | Spray Tower Reactor |

| Heating | Outside (Inside) Coil Heating |

| Heat Transfer Structure | Jacketed |

| Automatic Grade | Automatic |

| Condition | New |

| Transport Package | Iron Bracket |

| Specification | 500-10000 L |

| Trademark | TAIJI |

| Origin | China |

| HS Code | 3703951845 |

| Production Capacity | 30000 Sets/Year |

Product Description

Product Name: K Type Glass Lined Reactors

Another Name: Open Type Glass Lined Reactors

Subordinate category: Glass Lined Reactor

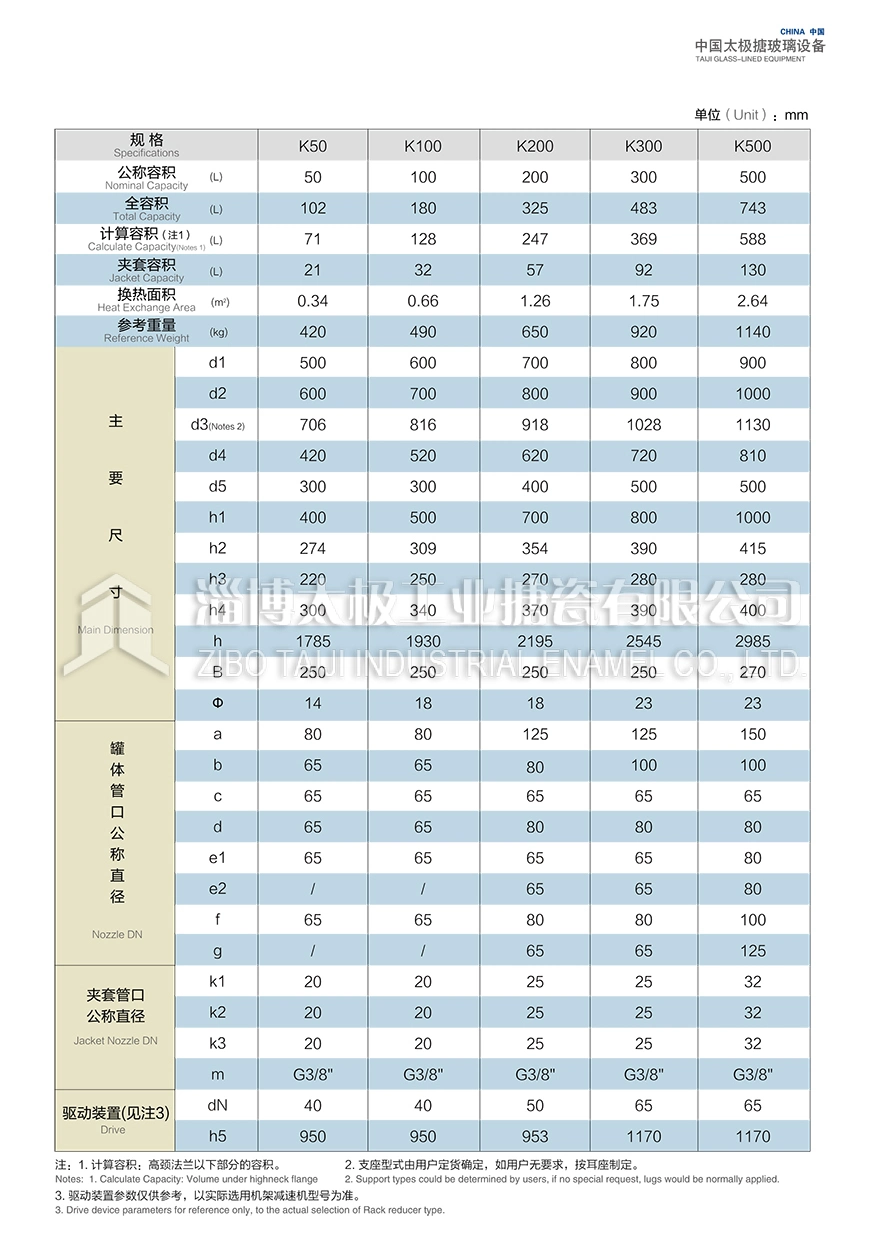

Product Capacity: 50L\100L\8000L \ 10000L \ 12500L \ 16000L

Product Standard:ASME \ PED \ RTN

Product Use: As the best equipment for hydrolysis, neutralization, crystallization, mixing, and emulsifying, the K Type glass lined reactor is widely used in the chemical, petroleum, pharmaceutical, pesticide, food, dye, and other industries.

Product Introduction:

Then Open glass lined reactor is containing high silica glass lined glaze spraying on the surface of the steel container, by high temperature burning process reasonable and firm adherence to the surface of the metal into composite material products, the tank cover glass lined reactor can be separated and tank, is arranged between the sealing gasket through the clip after a week fixed.

Easy to use, easy to maintain and maintain. It has the double advantages of glass stability and metal strength. It is an excellent corrosion resistant chemical equipment. It has corrosion resistance, impact resistance, smooth appearance, insulation, heat resistance, wear-resistant and other reliable performance. Glass lined equipment, such as glass lined reactors, are widely used in chemical, petroleum, pharmaceutical, pesticide, food, dye and other industrial processes. They are the most ideal equipment for hydrolysis, neutralization, crystallization, mixing and emulsification.

Related Products

-

![Laboratory Consumable 5ml 10ml 25ml 50ml Highly Transparent PP Disposable Sterile Serological Transfer Pipettes]()

Laboratory Consumable 5ml 10ml 25ml 50ml Highly Transparent PP Disposable Sterile Serological Transfer Pipettes

-

![Inexpensive Factory Vacuum Suction System]()

Inexpensive Factory Vacuum Suction System

-

![Excellent Quality Reactor Tank Photochemical Esterification Reactor]()

Excellent Quality Reactor Tank Photochemical Esterification Reactor

-

![High Power Liquid Water Ring Vacuum Pump and Compressor Roots Pump 2be Oil-Less Piston Rotary Vane Pump]()

High Power Liquid Water Ring Vacuum Pump and Compressor Roots Pump 2be Oil-Less Piston Rotary Vane Pump