99% High Efficient Essential Full Spectrum Essential Wiped Film Short Path Distillator

Changzhou Chance offers MD series stainless steel molecular distillation turnkey solutions (from lab scale to industrial

Send your inquiryDESCRIPTION

Basic Info

| Model NO. | EMD-160 |

| Material | Stainless Steel |

| Condition | New |

| Film Forming System | Scraper |

| Machine Material | High Boro.3.3/ SUS 316L/SUS 304 |

| Purity | 75%~95% |

| Max. Speed | 500rpm |

| Effective Distillation Area | 0.2m2 |

| Barrel Size | 160mm |

| Feeding Flask | 5L |

| Feeding Rate | 5-15kg/H |

| Motor Power | 120W |

| Usage | Distillation |

| Sealing Material | PTFE |

| Transport Package | Wooden Case |

| Specification | Customized |

| Trademark | Chance |

| Origin | China |

| HS Code | 8419409090 |

| Production Capacity | 1 Set/ 60 Working Day |

Product Description

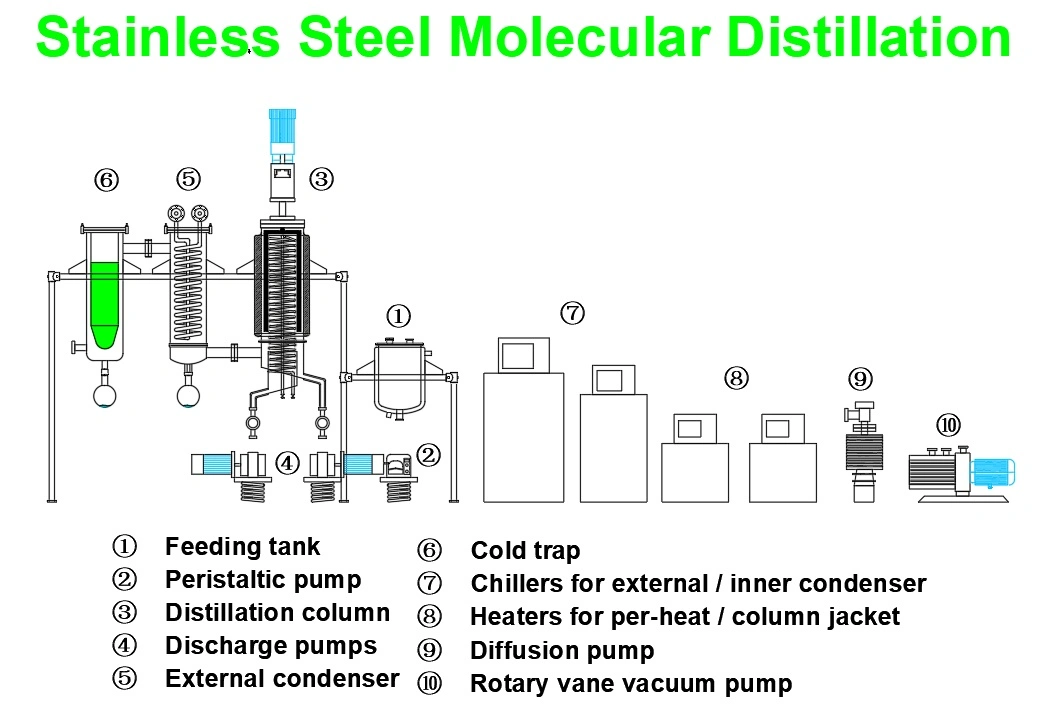

Changzhou Chance offers MD series stainless steel molecular distillation turnkey solutions (from lab scale to industrial scale). The short residence time and low separation temperature of molecular distiller make it one of the best separation equipment. The equipment includes evaporator, vacuum pump, heater, cooler and necessary feeding / receiving equipment. The equipment is available in various sizes (80mm, 100mm, 150mm, 200mm and more).

General Features

The heat transfer rate of stainless steel is much faster than that of glassware, and the processing speed is extremely high.Plug and play turnkey project, and provide technical support.All parts are made of SS304, which has excellent durability.Provide engineer on site service (to be negotiated).

Equipment structure

Product model

| Model | EMD-100 | EMD-160 | EMD-210 | EMD-300 |

| Feeding rate (kg/h) | 2~7 | 5~15 | 10~20 | 18~36 |

| Effective evaporation area (m2) | 0.1 | 0.2 | 0.3 | 0.5 |

| Evaporation tube diameter(mm/inch) | 110/4.3" | 160/6.3" | 210/8.3" | 300/11.8" |

| Wiper material | SS316L/PTFE (wiper blade) | |||

| Vacuum seal | Magnetic seal | |||

| Motor power(W) | 120 | 120 | 180 | 750 |

| Speed regulation mode | Variable frequency drive | |||

| Motor speed (rpm) | 0~500 | |||

| Working temperature (ºC) | RT~250 | |||

| Feeding vessel volume(L) | 10 | 20 | 30 | 50 |

| Evaporation area of inner condenser(m2) | 0.2 | 0.4 | 0.6 | 1.8 |

| Heating mode | Jacket heating/Electric heating | |||

| Receiving flask (L) | 2 | 5 | 10 | 30 |

| Feeding pump | Peristaltic pump | |||

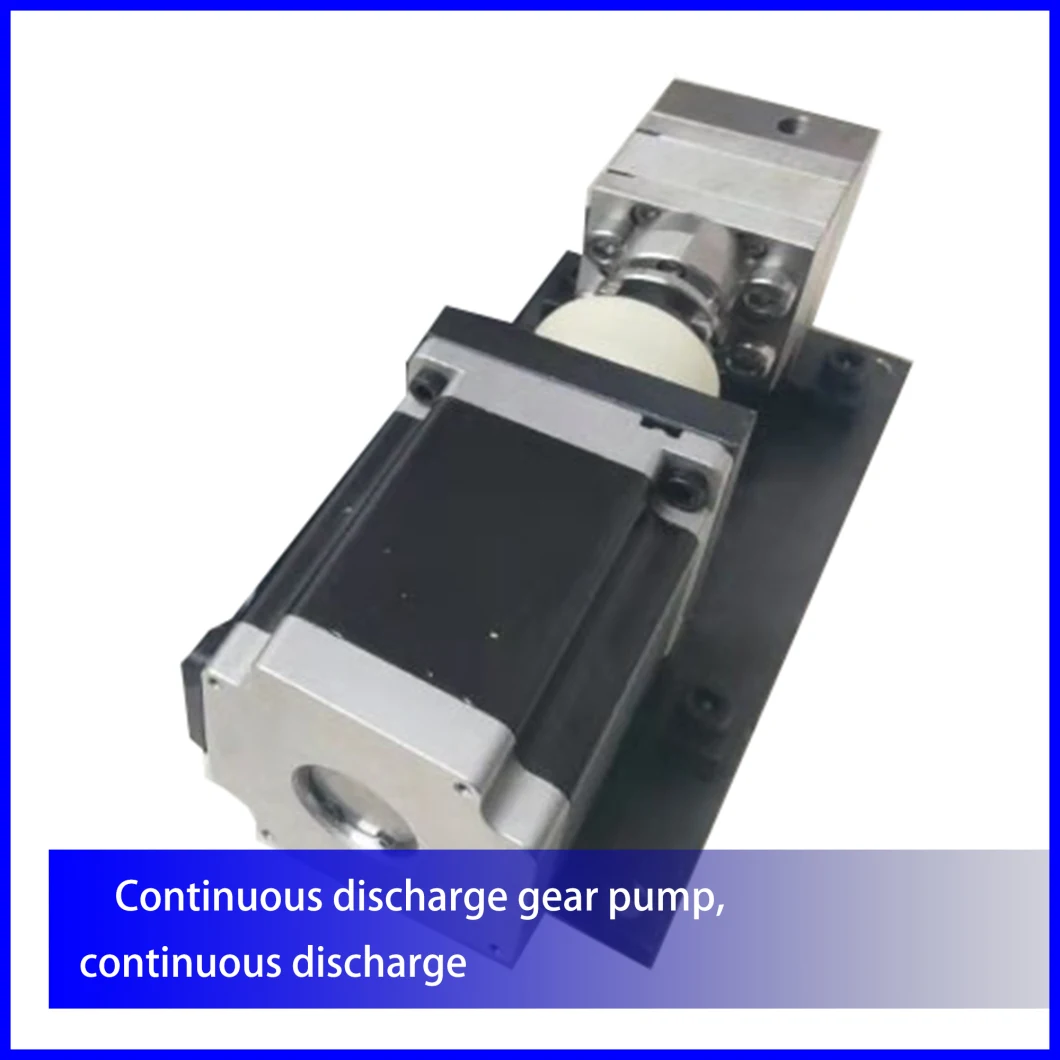

| Discharge pumps | Gear pump (option) | |||

| Power supply | 220V single phase/ customized | |||

Product introduction

Related Products

Packing & Shipping

Changzhou chance offers standard carton packaging and wooden case packing with inner protection (lightweight material with protection). Some foam board and bubble film will be put in the inner packing to prevent damage or other breakage caused by human error during loading and unloading. Transportation: by sea or by air, as you wish. (TNT, UPS, FedEx, EMS, DHL, SF or other logistics).

About Us

Changzhou Chance was founded in Changzhou, specializing in the production and sales of high-quality oil extraction and distillation equipment from plant biomass.

We are committed to becoming a turnkey solution provider for plant oil extraction and distillation equipment. Our goal is to provide customers around the world with the best products and quality service.

We rely on our own quality supply chain, with reasonable prices and real-time support to supply all products.

We are proud to guarantee that by choosing us, you will get high quality solutions and products.

FAQ

Q: How long is your delivery time?

A: Generally it is within 30~45 working days after receiving the payment

Q: What Is your terms of payment?

A: Western Union,T/T and L/C.100% Payment before shipment or as negotiated terms with clients

Q: What's the MOQ?

A: No MOQ for standard products.Custom parts can be discussedQ: Do you have product warranty?

A: Yes,12 months warranty.100% inspection on finished products before dispatch.Repair parts could be supplied for replacementCustom facbrication is acceptable.Any customer wants to be our distributor and partner.You will get favorbale support!

All our products are customizable. Any questions about wiped film molecular distillation units please send the email below to contact us.